Mobile : View Mobile Number

- GST No. 09BGNPS4001H2Z9

- Send SMS

- Send Email

Paper Processing Chemicals

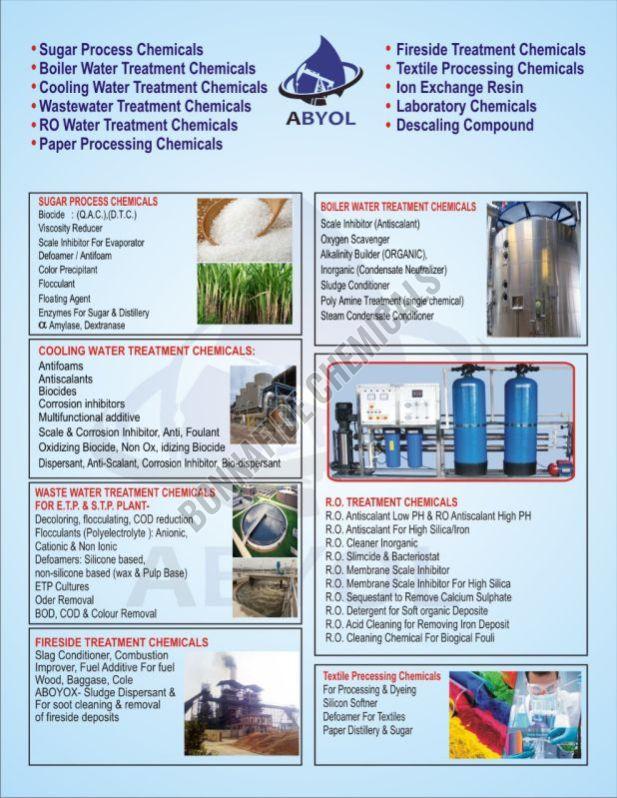

Leading Manufacturers, Exporters, Wholesaler and Trader of Ion Exchange Resin, Silicon Defoamer and Softener Resin from Kanpur.

| Business Type | Manufacturer, Supplier |

| Purity | ≥ 95%,99% |

| Viscosity | 500 - 5000 CP |

| Color | Pale Yellow |

| Country of Origin | India |

| Application | Industrial Adhesives,Art Applications,Coatings,Ion-exchange Processes |

| Odor | Mild Characteristic Odor |

| Curing Time | 1 - 24 Hours |

| Function | Adhesion,Coating,Molding,Ion-exchange Applications |

| Storage Temperature | 5°C - 35°C, Store In A Cool, Dry Place, Away From Direct Sunlight |

A "resin specification" is a set of quality requirements for a particular type of resin, which can include properties like appearance, viscosity, curing time, mechanical strength, and purity, often detailed in a technical data sheet or a national/international standard document (like those from ASTM or the Bureau of Indian Standards (BIS)). The specific parameters and tests required in a specification vary greatly depending on the resin's intended use, such as industrial adhesives, art applications, or ion-exchange processes.

| Business Type | Manufacturer, Supplier |

| Application | Foam Control In Pulping And Paper Manufacturing |

| Country of Origin | India |

| Pack Type | Drum |

| Type | Silicone-based Defoamer |

| Active Ingredients | Polydimethylsiloxane, Silica, Silicone Emulsions |

| Form | Water-dilutable Stable Emulsion |

| Working Conditions | Effective Under High Temperature And High PH |

| Functions | Defoaming, Anti-foaming, And De-airing Agent |

| Benefits | Reduces Foam Caused By Lignin, Rosin, And Soaps |

| Industry Use | Paper And Pulp Processing Plants |

BONNAFIDE CHEMICALS** Paper processing utilizes specialized silicone defoamers containing active ingredients like polydimethylsiloxane (silicone oil), silica, and silicone emulsions to control foam caused by lignin, rosin, and soaps during pulping and paper manufacturing. These water-dilutable, stable emulsions effectively break down foam bubbles, improving operational efficiency and the quality of the final paper product by acting as anti-foaming and de-airing agents in challenging high-temperature, high-pH conditions.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Form | Powder |

| Particle Size | 0.30 - 1.20 mm |

| Moisture Retention | 43 - 48% |

| Bulk Density | 0.78 - 0.88 G/ml |

| Total Exchange Capacity | ≥ 2.0 Meq/ml |

| PH Range | 0 - 14 |

| Maximum Operating Temperature | Up To 120°C |

| Regeneration | NaCl Solution, 8 - 10% Concentration |

| Storage | Store In A Cool, Dry Place Away From Direct Sunlight |

Bonnafide Chemicals Softener resin specification is defined by physical properties such as particle size (0.30-1.20 mm), moisture retention (43-48%), and bulk density (0.78-0.88 g/ml), as well as chemical characteristics including total exchange capacity (e.g., ≥ 2.0 meq/ml), pH range (0-14), and maximum operating temperature (up to 120°C), while recommended operating conditions involve high service flow rates (e.g., up to 45 bv/h) and NaCl regeneration at 8-10% concentration